Control of PV Systems on the Medium-Voltage Grid

Feed-in management (with Solar-Log™ PM Pro license)

In Germany, PV plants that are connected to the medium-voltage grid are subject to extended requirements. The different regulations that may be applied in a plant are bundled in the VDE-AR-N-4110 (VDE-4110).

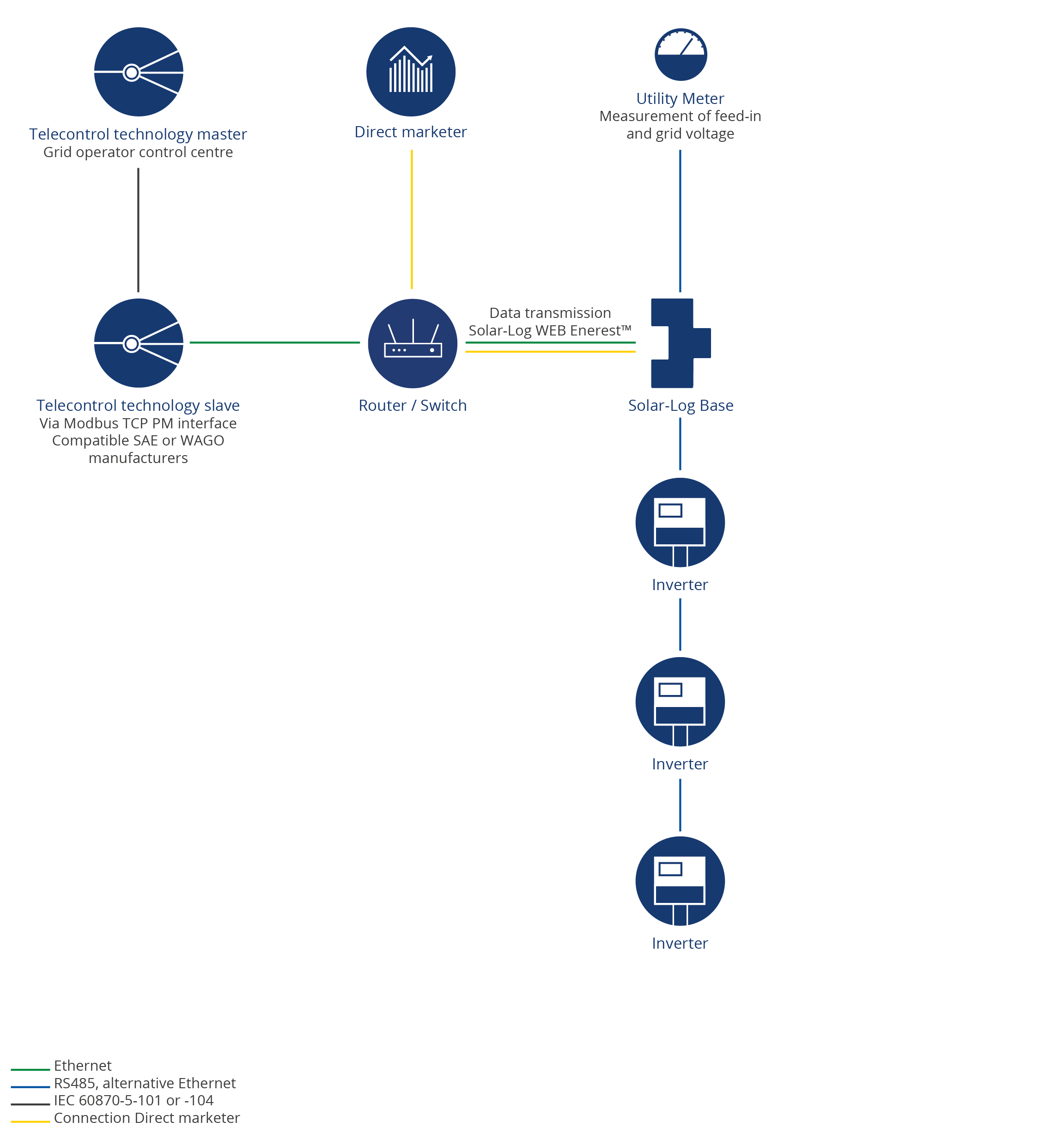

As a rule, in addition to the type of control of the PV system, it is also stipulated that various information about the current status of the PV system must be made available to the energy company.

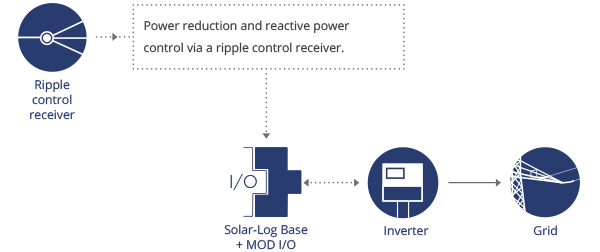

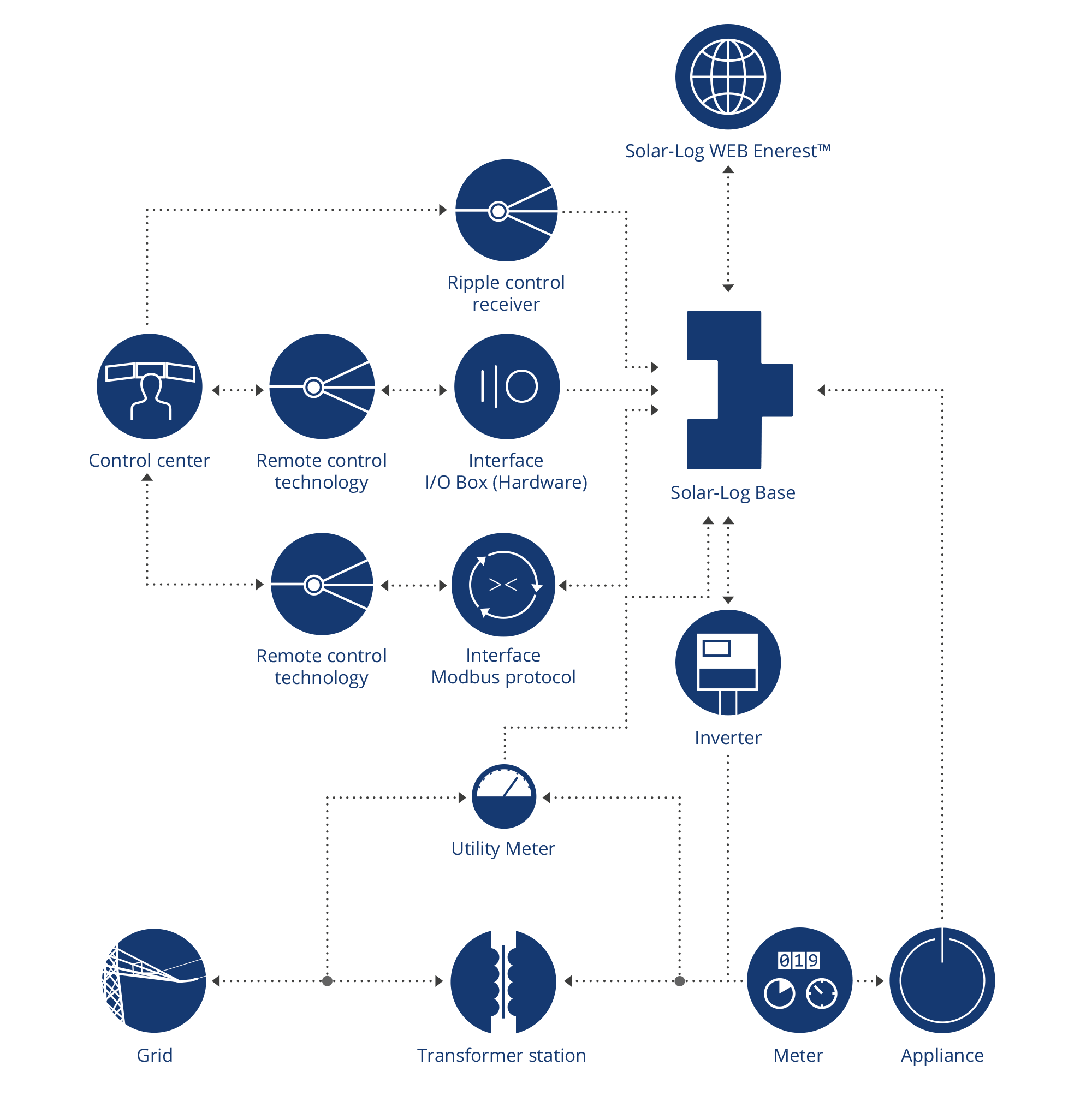

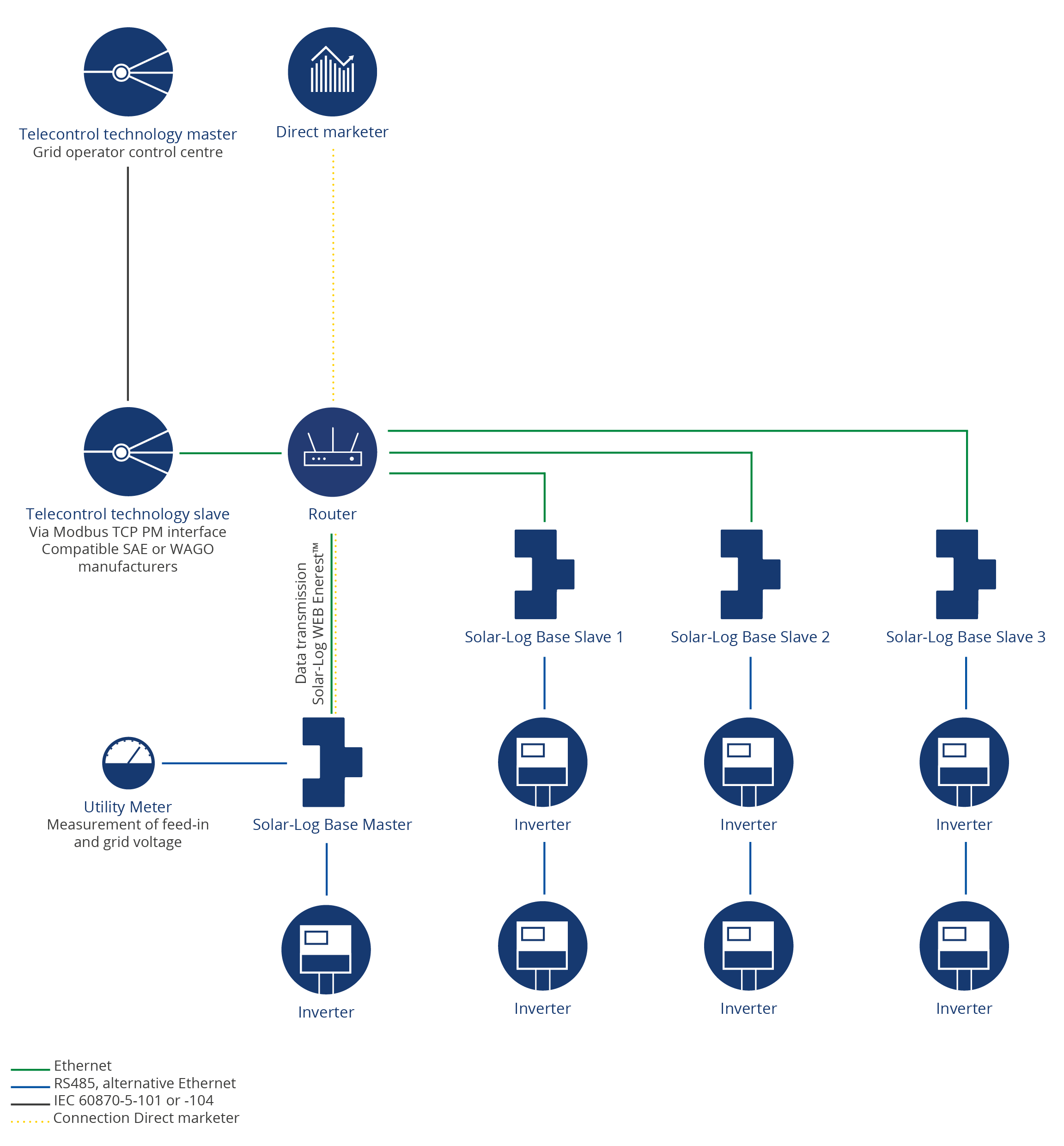

Communication with the energy company is implemented via telecontrol systems. Signal transmission between the telecontrol system and the Solar-Log™ Base normally takes place via a Modbus/TCP interface, more rarely via the I/O box(es) (analog, digital) included in the PM package. In addition to the control of active power, reactive power control presents a particular technical challenge.

VDE-4110 provides for various voltage - or power-controlled concepts here. The voltage-guided reactive power control requires a measurement at the feed-in point, for this a Solar-Log™ GmbH approved meter (Utility Meter) is required.

Component certificate according to VDE-AR-N-4110